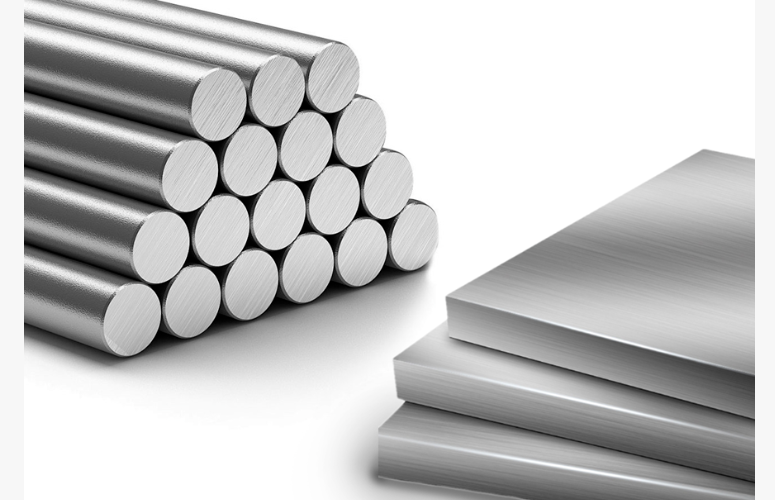

In-Depth Analysis of Material Properties

Structural Advantages of Bars

Manufactured through extrusion processes (producing round, square, hexagonal, and other profiles), bars exhibit highly aligned internal grain flow. This structural characteristic provides exceptional mechanical properties along the longitudinal direction, making them particularly suitable for applications involving axial loads and torque transmission.

Typical Applications: Precision mechanical transmission systems, where shaft components machined from bars ensure operational accuracy and long-term wear resistance.

Planar Characteristics of Sheets

Produced via rolling or casting processes into flat rectangular forms, sheets offer excellent surface flatness and uniform thickness tolerance. These properties provide an ideal foundation for subsequent forming operations and surface treatments.

Typical Applications: Vehicle body panels in transportation equipment, where stamping processes enable precise formation of complex curvatures while maintaining high surface quality.

Selection Framework

Geometric Considerations

-

Bars are preferred for: Axisymmetric components, structures with high length-to-diameter ratios

-

Sheets are preferred for: Large planar structures, components requiring complex curved surfaces

Mechanical Performance Requirements

-

Bars excel in: Unidirectional loading scenarios, torque transmission applications

-

Sheets excel in: Multi-directional load-bearing structures, applications requiring in-plane load capacity

Manufacturing Process Considerations

-

Bar processing: Suitable for subtractive manufacturing (turning, milling), simplified fixturing

-

Sheet processing: Ideal for forming operations

-

(stamping, bending), efficie

-

nt for batch production

Cost Structure Analysis

Economic Characteristics of Bars

Relative lower raw material costs, particularly economical for small components. The regul

ar geometry enables higher material utilization during processing, while requiring less specialized tooling investment.

Cost Considerations for Sheets

Material costs increase with special specifications, requiring significant upfront investment in molds and equipment. However, large-scale production achieves substantial unit cost reduction through economies of scale, particularly in automotive manufacturing and other high-volume industries.

Implementation Recommendations

Material selection should integrate product design requirements, manufacturing feasibility, and overall economic efficiency. Prototype testing and cost modeling are recommended to identify the optimal material solution for specific projects, ultimately achieving the best balance among product quality, production efficiency, and cost control.